Controlling Cold Storage Temperatures, Traffic and Costs

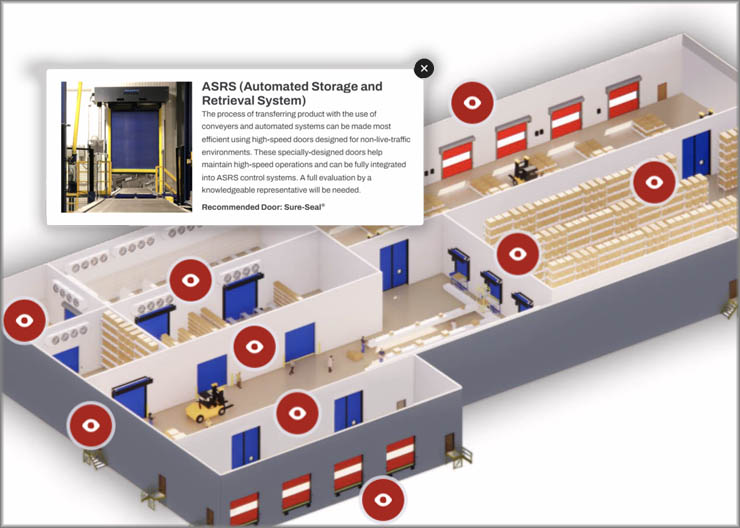

The primary challenge for dry, refrigerated and frozen food distributors is control — controlling the environment, controlling traffic, and controlling costs. With these concerns in mind, Rytec introduced the very first high-speed folding door for the cold storage industry over 30 years ago and remains in firm control of cold storage doors today. Since then, Rytec has expanded this line of doors to address all aspects of food preparation and storage. From meat cutting and banana ripening cold rooms doors to freezer room doors and the ever-growing automated storage and retrieval system (ASRS) doors, like the Sure-Seal door, for facilities using state-of-the-art technology to store, pick and ship goods quickly.

See our wide range of cold storage doors below for your specialized needs.

Resource Downloads:

Common Cold Storage Environments

- Refrigerated/Freezer Warehousing

- Food Processing

- Food Distribution

- Pharmaceutical/Nutraceutical

- Cosmetics

- Other Temperature-Sensitive Applications

Temperature and Environmental Control

- High-speed opening and closing minimizes air exchange

- Effective perimeter seals, thermal breaks and thermal panel help maintain temperature differentials

- Perfect for coolers, freezers, dry storage, produce, automated storage/retrieval, blast freezers and USDA/FDA processing

Reduced Energy and Maintenance Costs

- Less air infiltration leads to lower refrigeration costs

- State-of-the-art insulated panels eliminate the need for conventional defrost systems in many cases

- Self-repair, break-away, and resetting options help reduce maintenance costs

Cold Storage Case Study

Rytec helped Dade Service Corporation install doors at a national grocery retailer’s central distribution facility.

Selecting the Right Cold Storage Door

Download our 2nd edition FREE Guide: Knock Temperature Differentials Out Cold – with High Performance Doors. You Will Learn the How and Why of:

- Assessing Temperature Needs

- Solutions for Temperatures Above Freezing

- Solutions for Temperatures Below Freezing

- The Importance of Size and Clearance

- Safety Remedies to Protect staff, Products & Equipment

Recommended Doors for the Cold Storage Industry

FlexTec®

Flexible soft-edge door with industry’s longest mechanical warranty and opening speed up to 100 ips.

Plexline®

High-performance rolling door with quick opening speeds and tight seals for control and maintenance of temperatures and environmental conditions.

PredaCool™

Single panel design allows this high-performance rolling door to function at higher speeds for greater environmental control for cold storage operations.

PredaDoor® NXT®

Versatile and durable high-performance rolling door provides unprecedented reliability for numerous interior and exterior applications.

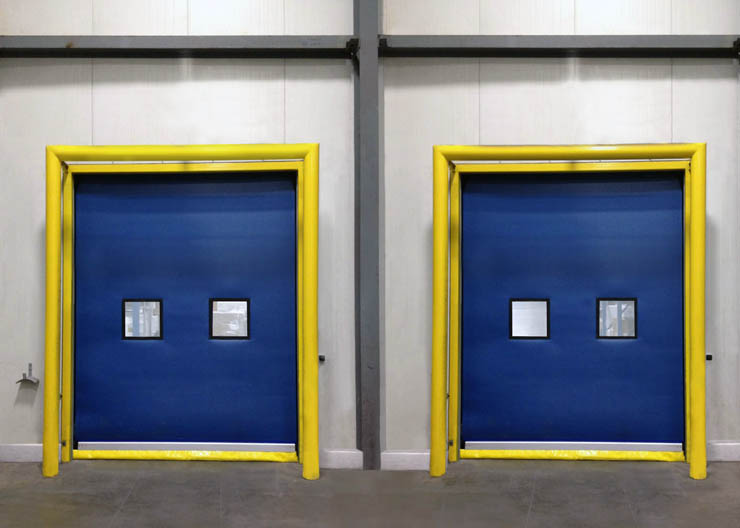

Sure-Seal®

Designed to keep automated storage and retrieval system environments – using conveyor-type product transport – highly insulated, productive and energy efficient.

Turbo-Seal® Insulated

Fastest, most energy-efficient insulated door increases productivity and reduces energy costs for cold storage and food and beverage operations.

Turbo-Slide®

High-performance sliding door provides unprecedented speed, insulated R-value and impact resistance for cold storage and food and beverage facilities.

Related Articles

Choosing the Right High-Performance Doors for Cold Storage Facilities

Maintain temperatures, enhance efficiency and save energy by choosing the right high-performance doors for all areas of your cold storage facility.

Fresh Perspectives: High-Speed Doors in Cold Storage Facilities

Invest in high-performance doors for cold storage to maintain temperatures, enhance efficiency, save energy, and improve safety and compliance.

The Secret to Smooth Operations in Cold Storage and Food and Beverage Facilities: High-Performance Doors

High-performance doors keep the environment, equipment, people and costs under control in cold storage and food and beverage facilities.