In manufacturing facilities, doors must be reliable for the factory to maintain peak efficiency. Here’s how high-performance doors help.

Stainless steel or composite materials help maintain clean rooms.

Quick opening speeds & tight seals for temperature control.

Improve security & traffic flow and enhance architectural style.

Withstand winds up to 175 mph and comply with the Florida Building Code.

Increase productivity & address stringent USDA, FDA & cGMP requirements.

High-speed & perimeter seals minimize the air exchange between areas.

High speed & durability ensure secure access.

Perforated or screen door panels allow improved air circulation.

When time is of the essence, high speed and reliability are crucial.

Fast cycle times and secure seals keep environments separated.

Rugged design & secure seal for oversized openings.

Break-away functionality with rugged design seals oversized openings.

Withstands challenges of heavy equipment and fleet truck/car wash environments.

Fast opening speeds and reliable, durable construction keep facilities secure and protected.

Reduce energy costs, increase productivity and comfort and enhance customer perception.

Increase productivity and operational efficiency while reducing energy and maintenance costs.

We offer solutions for Apartment / Condo & Loft, Standalone Parking Facilities and Office Buildings

Doors specifically engineered for USDA/FDA and cGMP environments, and assured compliance for uncompromising performance.

A complete product line allows facilities to increase efficiency and safety and reduce maintenance and energy costs.

Ensure effective security and environmental controls are maintained for critical government operations.

Keep operations running smoothly and efficient while reducing energy and maintenance costs.

Doors that offer quick, secure access, environmental control and reliability for life science facilities.

In manufacturing facilities, doors must be reliable for the factory to maintain peak efficiency. Here’s how high-performance doors help.

Cold storage facilities are getting taller to reduce their real estate footprint. So are the high-performance doors used to keep them running efficiently.

High-performance doors used in cold storage, food and pharmaceutical production must meet strict FDA and cGMP regulations. Here’s what you need to know.

High-performance doors deliver reliable performance. That’s because they’re built for longer life expectancy than conventional doors. Here are 4 examples.

Understanding the R-value of doors is critical in the cold storage industry, where minimizing heat loss and maximizing energy efficiency is a must.

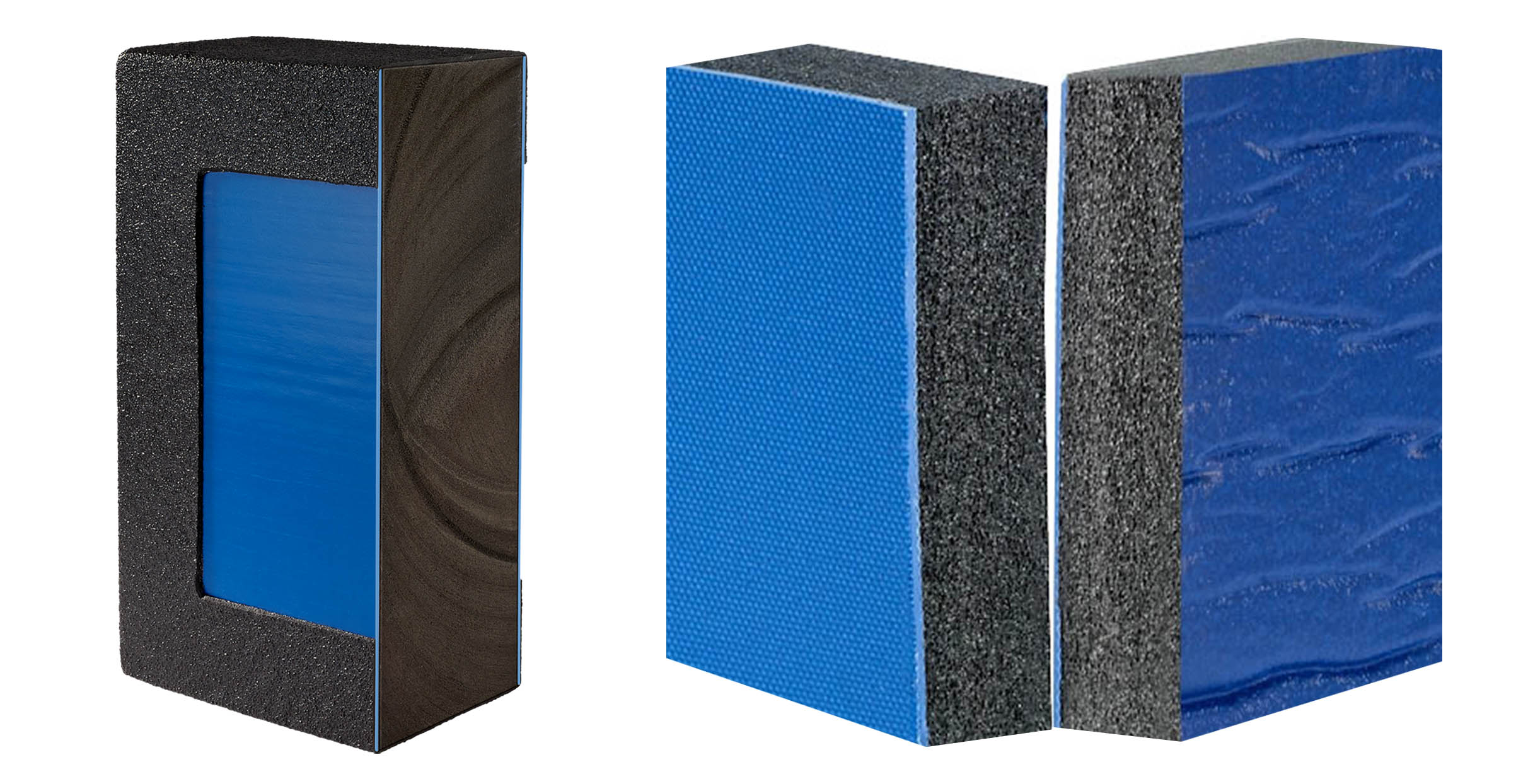

The first step to ensuring a safe and clean environment is a high-performance clean room door. Here are the qualities and capabilities to look for.

If you’re using traditional overhead doors in your cold storage or food production facility, you may be experiencing significant energy loss.

High-performance doors help loading docks keep up with today’s peak demand cycles. Here are door types used in this environment and common features.

High-performance doors provide food processing and distribution facilities with reliability, speed and efficiency to meet today’s growing consumer demand.

Several styles of high-performance doors can help manage a variety of cold storage conditions. Here’s how to select the right one for your needs,

Safety is Job One in any environment that uses high-performance doors. Safe, secure door opening and closing is crucial. Safety signaling devices help. Here’s how.

For facilities with automated storage and retrieval systems (ASRS), high-performance doors are critical to maximizing energy efficiency and performance..